电子束加工是一种过程,其中高速电子浓缩成窄梁,然后朝向工件朝向机械加工。当该高速电子撞击工件时,它将其熔化并蒸发材料从工件中蒸发。

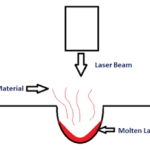

Working Principle of Electron Beam Machining

In an electron beam machining, the electrons strike the workpiece with a high velocity. As the electron strikes the workpiece, the kinetic energy of the electron changes into heat energy. The heat energy so produced is used to melt and vaporize the materials from the w/p. The whole process takes place in vacuum. Vacuum environment is used to prevent the contamination and avoid collision of electrons with air molecules. If the electrons collide with the air molecules, it will lost its Kinetic energy.

Electron Beam Machining Diagram

Equipment of Main Parts

The various equipment used in EBM machine are

1.阴极

阴极带负电,使用它来产生电子。

2.环形偏置栅格

It is present next to the cathode. Annular bias grid is a circular shaped bias grid and prevents the diversion of electrons produced by the cathode. It works as a switch and makes the electron gun to operate in pulse mode.

3. Anode

It is placed after the annular bias grid. It is positively charged. Annular anode attracts the beam of electron towards it and gradually the velocity of the electron increases. As the electron beam leave the anode section, its velocity becomes half of the velocity of light.

Also Read:

- Water Jet Machining – Working Principle, Advantages and Disadvantages with Application

- 激光束加工 - 主要零件,原理,使用应用

- Ultrasonic Machining (USM) – Main Parts, Working Principle, Advantages and Disadvantages with Application

4.磁性镜片

The magnetic lenses reduce the divergence of electron beam and shape them. It allows only convergent electrons to pass and captures the low energy divergent electrons from fringes. It improves the quality of the beam.

5. Electromagnetic Lens

It helps the Electron beam to focus on the desired spot.

6. Deflector Coils

The deflector coil carefully guides the high velocity electron beam to a desired location on the workpiece and improves the shape of the holes.

Working of Electron Beam Machining

- 在EBM中,首先通过阴极产生电子,并且环形偏置网格不允许电子传递。

- From the annular bias grid, the electron produced by the cathode is attracted towards the anode and gradually its velocity increases. As the electron beam leaves the anode section, its velocity reaches to half of the velocity of the light.

- 之后,它通过了一系列磁镜头。磁透镜只允许收敛梁穿过它并捕获来自边缘的发散光束。然后使高质量的电子束穿过电磁透镜和偏转线圈。

- The electromagnetic lens focuses the electron beam to the desired spot on the workpiece. The deflector carefully guides the beam to the desired locations and improves the shape hole.

特征

- 电子束机以脉冲模式操作,并且这是通过偏置环形偏置栅格实现的。

- 电子束电流可以低至200μamp 1点p.

- EBM机器中实现的脉冲持续时间为50μs至15ms。

- The energy possessed by the pulse is 100 j/pulse.

- It utilizes voltage in the range of 150 kV to 200 kV. And this voltage is used to accelerate Electrons to about 200,000km/s.

优点

- 它可以产生小尺寸的螺栓。

- High accuracy and better surface finish.

- Almost all types of materials can be machined.

- Highly reactive metals such as Al and Mg can be machined easily.

- As it does not apply any mechanical cutting forces on the workpiece, so cost of work holding and fixtures is reduced.

缺点

- High equipment cost:The cost of the equipment in this machining is quite expensive.

- Low metal removal rate:The metal from the workpiece is removed at the slower rate.

- 高技能操作员:对于操作电子束机,需要高熟练的操作员。

- 高功耗:它在其操作中消耗了高功率。

- Not applicable to produce perfectly cylindrical deep holes.

Application

电子束加工用于在汽车,航空航天,海洋等行业中生产较小的尺寸孔。